Material Cutting

Gear Lock aftermarket auto tool

Whether you’re looking for intricate designs or straight forward cuts, our team ensures unmatched precision on every project.

Whether you're looking for intricate designs or straightforward cuts, our team ensures unmatched precision on every project.

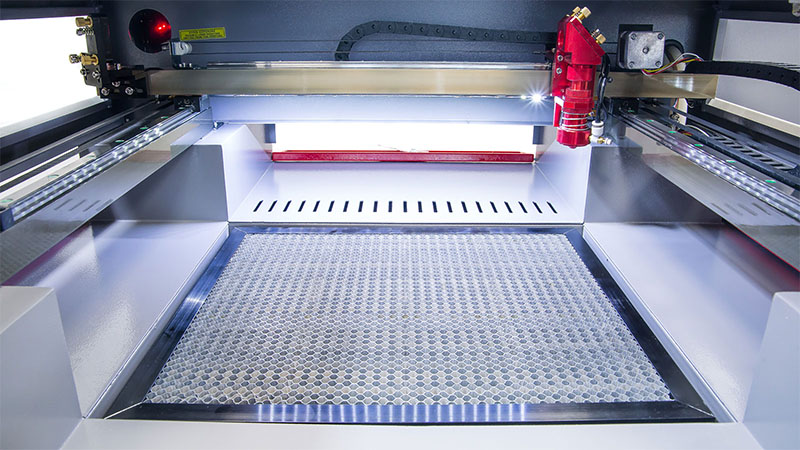

Laser Cutting

Elevate the quality and speed of your manufacturing projects with our precise and efficient laser cutting. CNC Laser cuts steel up to 1/2” thick within .001” tolerances; and aluminum up to 1/4” thick within .001” tolerances.

Plasma Cutting

our advanced plasma cutters handle thicker metals with exceptional speed and precision. CNC Plasma cuts steel up to 1/2" thick within .05” tolerances, up to 1-1/4” thick within .09” tolerance; and aluminum up to 1/2” thick within .07” tolerances.

Waterjet Cutting

the versatility of our waterjet cutter harnessing the force of high-pressure water mixed with abrasive materials to cleanly and accurately cut through a diverse range of materials. Cut up to 12” Aluminum and 9” Carbon steel , the majority of material below, tolerances are +/- .002” on thinner material and up to .1” on thicker material.

Based on tolerances, we’ll determine the most cost-effective method of cutting. We can nest your parts to minimize material usage, and pass the savings on to you. Volume discounts are available.

We’re a small Midwest contract manufacturer with over 30 years experience providing metal laser cutting, machining, assembling, welding and fabricating services to a wide variety of non-automotive industries including aerospace, heavy equipment, aftermarket tooling, outdoor equipment, and medical equipment.

Contact us or submit a quote.

We'll contact you to discuss your project.

We'll create a quote based on your specs along with a timeline.

“First article” can be issued per customer’s request.

During production, first, middle, last quality inspection will be completed.

We ensure final product is finished and delivered on time and on-budget.

Manufacturers often face several common problems when working with contract manufacturers. These problems can impact various aspects of the manufacturing process, and the quality of the final product. Some of the key challenges include:

Working with Arete mitigates these challenges because we have over 30 years' experience, the right equipment and a commitment to delivering consistent quality at a competitive price.

Our metal cutting services support a variety of metal materials, including: Steel, Stainless Steel, Tool Steel, Spring Steel, and Aluminum.