Contract Manufacturing

Reusable dunnage for medical beds

Transforming your concept into the exact product you need, our team ensures unmatched precision on every project.

Manufacturers often face several common problems when working with contract manufacturers. These problems can impact various aspects of the manufacturing process, and the quality of the final product. Some of the key challenges include:

Working with Arete mitigates these challenges because we have over 30 years' experience, the right equipment and a commitment to delivering consistent quality at a competitive price.

Arete Products and Manufacturing can help you increase efficiency and reduce costs without sacrificing quality or delivery times. We specialize in providing two categories of products:

Components

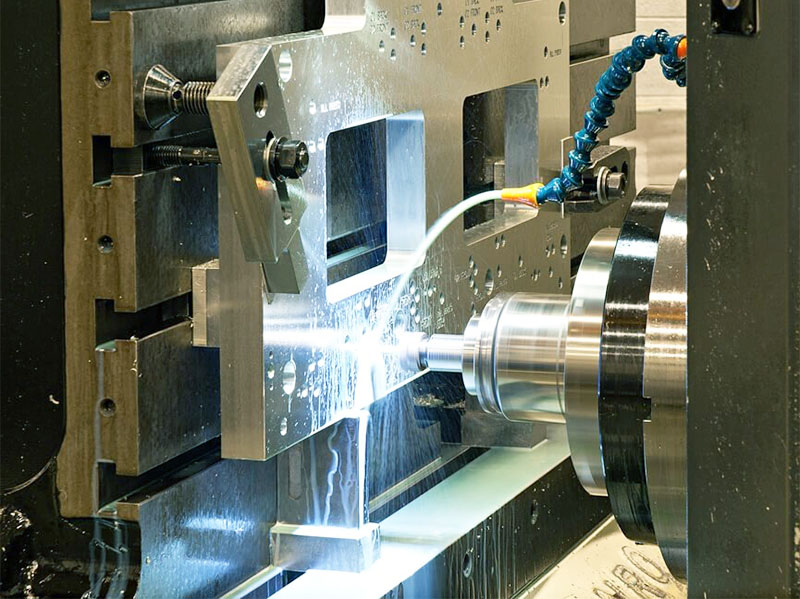

Our precision CNC machining capabilities are utilized to produce a wide variety of components such as shafts, rings, plugs, body/housings, and the list goes on. We also have the ability to modify an existing component to our customer's needs.

With production capabilities ranging from just a few parts to thousands, Areté Products & Manufacturing can produce your parts in a timely and cost-effective manner.

Assemblies and Sub-assemblies

We specialize in constructing full assemblies or sub-assemblies from components we manufacture. We can also facilitate the procurement of components to build assemblies.

Additionally, we can assemble complete or partial units with parts provided by our clients. Our adaptability enables us to integrate both our own and customer-supplied components in the assembly process.

To enhance our offerings, we also provide finishing services like plating, painting, and powder coating.

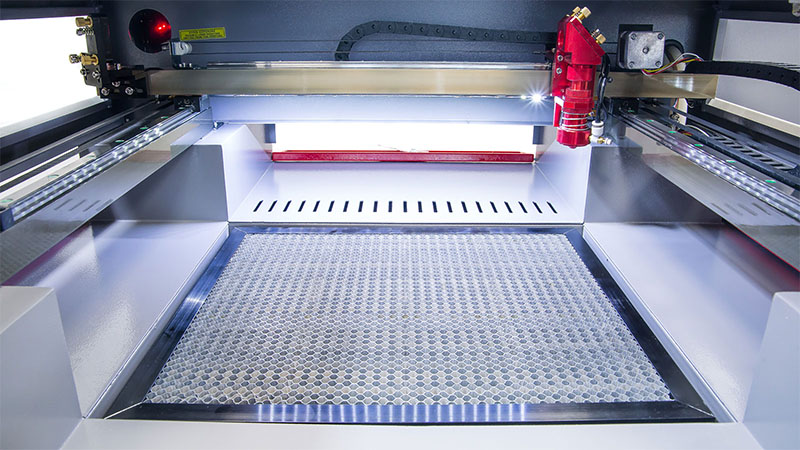

We’re a small Midwest contract manufacturer with over 30 years experience providing metal laser cutting, machining, assembling, welding and fabricating services to a wide variety of non-automotive industries including aerospace, heavy equipment, aftermarket tooling, outdoor equipment, and medical equipment.

Contact us or submit a quote.

We'll contact you to discuss your project.

We'll create a quote based on your specs along with a timeline.

“First article” can be issued per customer’s request.

During production, first, middle, last quality inspection will be completed.

We ensure final product is finished and delivered on time and on-budget.